In modern electrical infrastructure, choosing the right earthing material is one of the most important decisions for ensuring safety, system efficiency, and long-term reliability. Contractors, builders, industrial planners, and electrical engineers are constantly evaluating which conductor delivers the best performance: GI Earthing Strip or Copper Earthing Strip.

As a leading GI Earthing Strip Manufacturer Mumbai, we frequently receive the same question—“Which one should I use for my site?”

This detailed guide compares both options using engineering principles, cost analysis, conductivity studies, installation conditions, and safety standards. If you are a business owner, contractor, or industry professional searching for a definitive and practical comparison, this article will help you make the right choice.

Understanding the Purpose of Earthing Strips

Earthing strips are metallic conductors installed to safely dissipate fault currents into the ground. They protect:

- Electrical panels

- Machines and industrial equipment

- Power distribution systems

- Residential buildings

- Commercial complexes

- Telecommunication systems

A high-quality earthing system reduces:

- Shock risks

- Electrical fires

- System failures

- Equipment burnout

- Over-voltage damage

Choosing the right strip—GI or Copper—plays a critical role in this reliability.

What Is a GI Earthing Strip?

A GI Earthing Strip (Galvanized Iron Earthing Strip) is made by hot-dip galvanizing mild steel strips. The zinc coating acts as a protective barrier against corrosion and moisture.

Why GI Earthing Strips Are Popular

- Cost-effective

- Highly durable in normal soil

- Rust-resistant

- Suitable for large-scale installations

- Readily available

- Ideal for grounding basic electrical systems

As a GI Earthing Strip Manufacturer Mumbai, we supply GI strips widely for residential, commercial, and medium-load industrial applications.

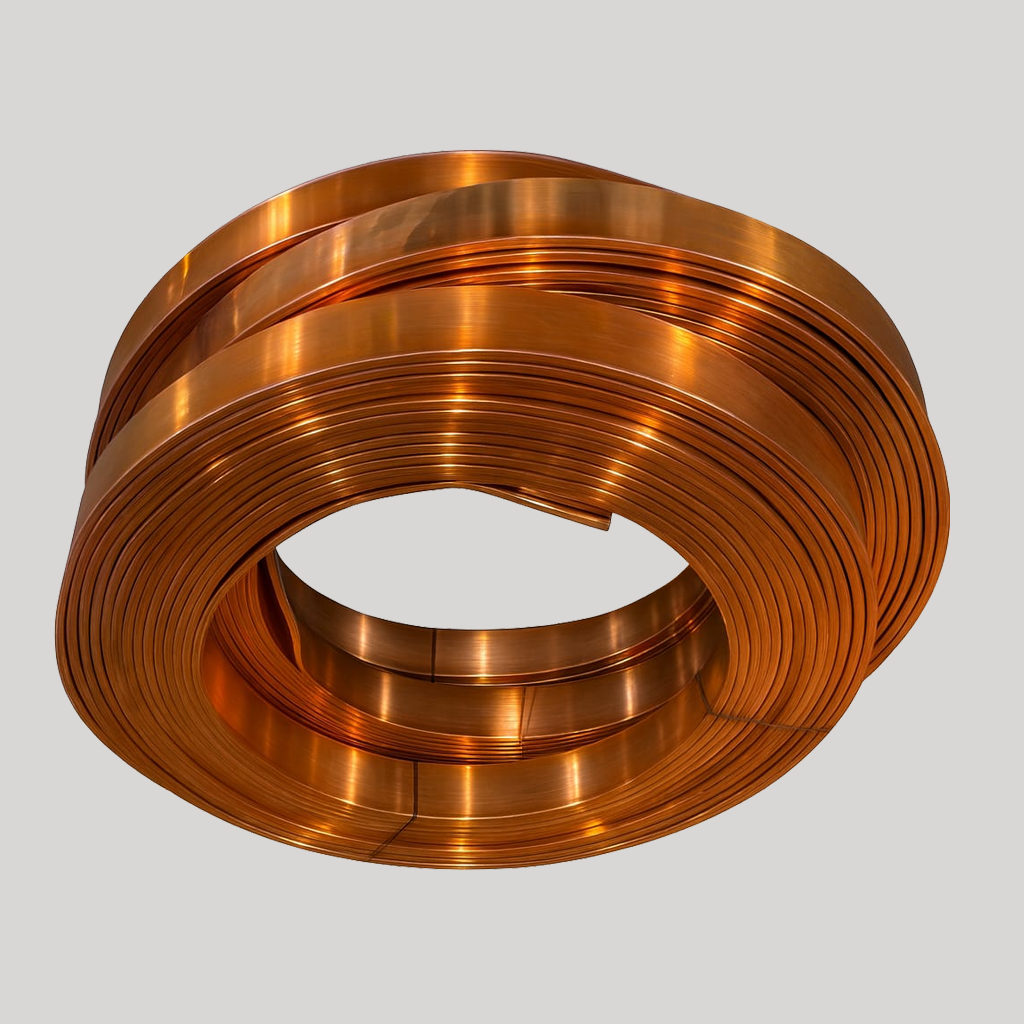

What Is a Copper Earthing Strip?

A Copper Earthing Strip uses pure or electrolytic-grade copper known for its superior electrical conductivity and corrosion resistance.

Where Copper Earthing Strips Excel

- High-conductivity environments

- Sensitive industrial equipment

- High-fault-current applications

- Chemical, saltwater, or acidic soil conditions

- Sites requiring long-term, maintenance-free earthing

Copper is the premium choice where performance is more important than cost.

GI Earthing Strip vs. Copper Earthing Strip: Detailed Comparison

Below is a practical 360° comparison engineered to help you make an informed decision.

1. Electrical Conductivity

Copper Earthing Strip

Copper is widely known as the second-best conductor after silver.

- Conductivity: 97% IACS

- Best for high-fault-current dissipation

GI Earthing Strip

GI has lower conductivity because its core is mild steel.

- Conductivity: 10–15% of copper

- Suitable for standard electrical loads

Verdict:

Copper wins for conductivity.

2. Corrosion Resistance

Copper

- Naturally corrosion-resistant

- Performs exceptionally in acidic, saline, and chemical-rich soils

- Lifespan often exceeds 40–50 years

GI

- Zinc coating provides rust protection

- In extremely moist or chemical soil, zinc can wear off faster

- Lifespan typically 15–25 years

Verdict:

Copper is superior in harsh soil.

GI is suitable for regular soil at lower cost.

3. Cost Comparison

Copper

- Expensive (up to 4–6 times the cost of GI)

- High initial investment

GI

- Very economical

- Best choice for budget-sensitive projects

Verdict:

GI is more affordable and therefore popular for large projects.

4. Soil Compatibility

GI Earthing Strip

Best suited for:

- Normal soil

- Low-moisture soil

- Mildly corrosive soil

Copper Earthing Strip

Best suited for:

- Highly corrosive soil

- Coastal environments

- Chemical plants

- Industrial zones

- Rocky soil with moisture variations

Verdict:

Choose based on soil testing.

5. Mechanical Strength

GI strips are generally thicker because mild steel offers better structural strength, making them suitable for harsh mechanical stress environments.

Copper strips, although strong, are softer and can bend more easily.

Verdict:

GI leads in mechanical strength.

Copper leads in flexibility and conductivity.

6. Current Carrying Capacity

Copper earthing strips dissipate fault currents far more efficiently due to their conductivity.

GI strips carry adequate current for standard electrical requirements but may not be ideal for high-fault-current industrial systems.

Verdict:

Industries requiring heavy machinery, transformers, or generators benefit from copper.

7. Longevity & Maintenance

Copper

- Minimal to zero maintenance

- Long lifecycle

- Sustains conductivity over decades

GI

- Requires monitoring after 10–15 years

- Zinc coating may diminish in harsh conditions

Verdict:

Copper provides long-term stability.

GI must be evaluated periodically.

Which Earthing Strip Is Best for Your Site?

Here is a practical guide to help professionals choose:

Choose GI Earthing Strip If:

- You need a cost-effective solution

- Soil is non-corrosive

- The load is moderate

- Mechanical strength is important

- Residential or commercial projects require standard earthing

- You need a reliable and budget-friendly option

GI strips are widely chosen by contractors, especially those working with tight budgets and large quantities.

If you’re searching for a GI Earthing Strip Supplier in Dombivli, these strips are ideal for bulk installation across developing residential zones.

Choose Copper Earthing Strip If:

- You require maximum conductivity

- Soil is highly corrosive or moisture-rich

- The site handles high-fault currents

- You want a maintenance-free system

- The project is industrial or mission-critical

- Long-term investment matters more than initial cost

Examples:

Chemical plants, data centers, power stations, telecom installations, and high-rise commercial towers.

Cost vs. Performance: The Real Engineering Answer

When deciding between GI and copper, the goal is not simply to choose the best material—it’s to choose the material that best suits your environment, budget, and electrical load.

Most Indian residential, commercial, and moderate industrial sites prefer:

- GI Earthing Strips for affordability and adequate performance

- Copper for special cases only

This is why an experienced GI Earthing Strip Manufacturer Mumbai can guide you by analyzing soil type, electrical load, and site requirements before recommending a solution.

Installation Scenarios: GI vs. Copper

Residential Projects

- GI Earthing Strip is the best fit

- Budget-friendly and meets regulatory requirements

Commercial Buildings

- GI is sufficient for office complexes

- Copper only if load is unusually high

Industrial Projects

Copper is recommended for:

- Transformers

- Generators

- CNC machinery

- High-fault-current systems

Coastal or Chemical Zones

- Copper provides long-term resistance

- GI may fail prematurely due to soil corrosion

Environmental and Safety Standards

While both materials are permitted under Indian electrical safety guidelines, copper meets higher global standards and is often mandated in sensitive industries.

GI adheres to IS 3043 and other local compliance frameworks.

Copper meets international safety standards like IEC, IEEE, and NEC.

GI Earthing Strip Supplier in Dombivli: Why the Location Matters

Dombivli is an emerging industrial and residential hub. Soil conditions here vary between:

- Moderately corrosive

- Moist

- Rocky regions

This makes GI strips suitable for large projects but requires soil testing before installation.

A well-experienced GI Earthing Strip Supplier in Dombivli can provide region-specific recommendations using data from previous installations.

Which Option Offers the Best ROI?

GI Earthing Strip – Best ROI for:

- Real estate

- Contract installations

- Commercial complexes

- Medium-load industries

- Budget-driven projects

Copper Earthing Strip – Best ROI for:

- Chemical industries

- Data centers

- Power plants

- High-value machinery sites

- Long-term operational ecosystems

Final Thoughts

Choosing between GI Earthing Strip and Copper Earthing Strip depends on the soil condition, electrical demand, environmental factors, and project scope. Both have advantages, but GI is the preferred choice for most standard applications due to cost-effectiveness and reliable performance.

DBA Earthing – Mumbai, India, a trusted GI Earthing Strip Manufacturer Mumbai, provides high-quality GI strips engineered for durability, conductivity, and safety. Whether you need a dependable supplier for bulk orders or expert recommendations for project-specific earthing solutions, DBA Earthing ensures professional-grade products and guidance tailored for your site.

Frquently Asked Questions (FAQs)

Q1. Which is better for residential projects: GI or Copper Earthing Strip?

GI Earthing Strips are the best choice for residential projects due to affordability and adequate performance.

Q2. Why choose a GI Earthing Strip Manufacturer Mumbai for my project?

Mumbai manufacturers offer region-specific expertise, fast delivery, and soil-appropriate product recommendations.

Q3. Is GI Earthing Strip suitable for industrial sites?

Yes, for moderate electrical loads. For high-fault-current industries, copper is recommended.

Q4. Do you offer GI Earthing Strip Supplier in Dombivli services?

Yes, bulk and project-based supplies are available specifically for Dombivli and surrounding industrial zones.

Q5. How long does a GI Earthing Strip last?

Depending on soil conditions, GI strips typically last 15–25 years, while copper lasts 40+ years.